ACCUFILTRONICS

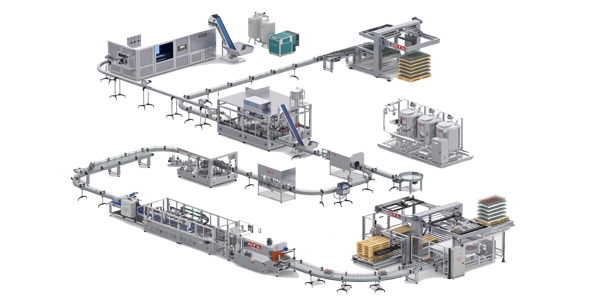

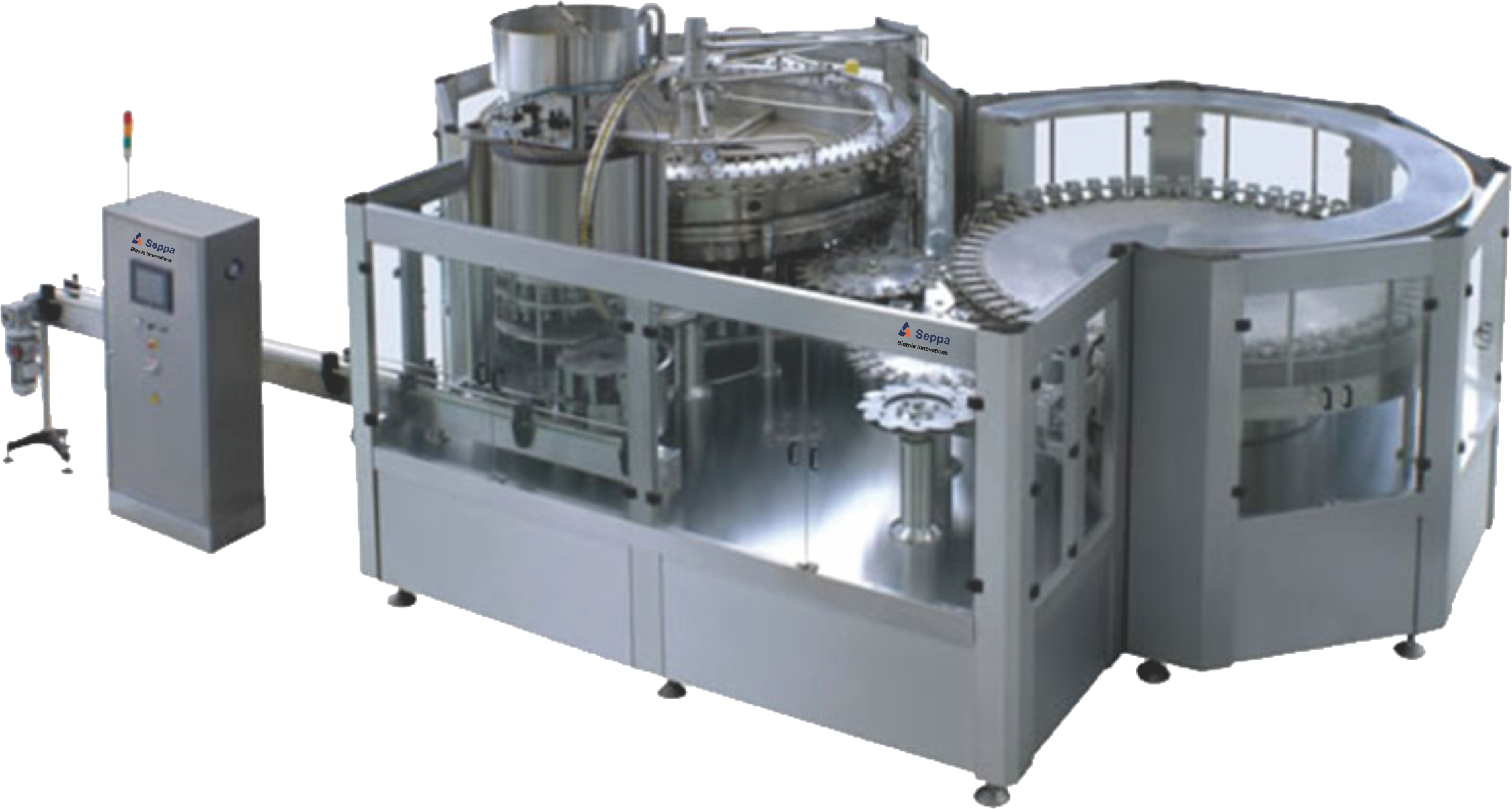

Modular range of electronic, volumetric filling monoblocs

A new, extremely innovative and flexible platform, which takes the standard SEPPA technologies to the highest level currently available on the market.

By taking advantage of the modular nature of all the elements of the platform, and choosing the most suitable filling valve, it is possible to create bespoke solutions for a wide range of bottling needs. In particular, the possibility of being able to fill several products on the same production line was one of our main aims when designing the ACCUFILTRONICS platform.

At the same time, we developed new EVF filling valves, created to be perfectly integrated and interchangeable as part of this new platform.

The range can be equipped with various different feeding solutions:

At the same time, we developed new EVF filling valves, created to be perfectly integrated and interchangeable as part of this new platform.

The range can be equipped with various different feeding solutions:

- from mixer/carbonator

- from pasteurizer

- from external tank

- from central tank on board

MODELS:

- GRAVITY ACCUFILTRONICS VM-GT-NC

- GRAVITY ACCUFILTRONICS VM-GT-HF-NC

- ISOBARIC ACCUFILTRONICS-VM -CP-HF -C

- GRAVITY ACCUFILTRONICS VM-GT-WF-NC

OUTPUT:

- Filler from 10 to 180 valves

- the output depends on the valve configuration and the product to fill

KEY FEATURES

- External or central tank (in case of pulpy products).

- Valve with magnetic flow meter for product dosing in each bottle.

- Entirely stainless steel (grade 304) draining base.

- No vent tube.

- Reduced changeover down-times.

- Simple to operate and great flexibility with selection of the various products/formats directly from the operator panel.

- PET bottle transfer - neck-handling - with no need for mono-block height adjustment.

- Sincro Bloc configuration available, for an integrated blowing- filling-capping solution.

- Controlled contamination cabin and cap sterilizing unit available in option in order to enhance hygienic standards.

- Extremely clean valves are ideal for the configuration of mono-bloc for cold filling of sensitive products without preservatives in Ultra Clean conditions.

- All the configurations can be produced with microbiological isolators, thereby minimizing the filling environment around the container.

ADVANTAGES

- Product deflection without deflector (swirl device) for version with contact between bottle and valve.

- Accurate volumetric dosing (no change-over).

- Filling speed adjustment to handle foaming products.

- Automatically engaged dummy bottles.

- Bottle snifting into a separate collector.

- The air in the bottle does not come into contact with the product feeding circuit.

- All parts in contact with the product are made of AISI 316L stainless steel (opt.).

- Quick changeover for bottles and necks with different diameters.

- "Dry" pressurization

- Simplified access for maintenance of the motor and the manifold

- Latest generation of electronic/pneumatic components, managed by an industrial PC.

FILLING VALVES-GRAVITY ACCUFILTRONICS VM-GT-NC

Is an electronic volumetric gravity filler for PET bottles, equipped with an extremely simple, clean and fast filling valve with no contact between valve and bottle, with a membrane valve to control the double filling speed.

This solution guarantees high flow performance.

Ideal for water, milk, homogenized juices and clear products.

The machine can be configured with mass flow meters, for filling of low conductivity products ( such as edible oil or deminaralised water)

Output

- Filler from 5 to 180 valves

- from 1.000 to 60,000 b/hour based on 190 ML TO 2 litres with water (ambient temp.).

FILLING VALVES-GRAVITY ACCUFILTRONICS VM-GT-HF-NC

Is an electronic volumetric gravity filler for PET bottles, equipped with “no contact”, double speed, shuttered filling valves.

Designed for HF applications in Ultra Clean configurations.

The valve-cleaning characteristics and the configuration of the mono-block make it particularly suitable for hot and cold filling of sensitive products such as premium fruit juices with pulps (non-homogenized).

The configuration for the valve makes it suitable for products with pulps and fibres, even with big dimension ones.

Output

- Filler from 10 to 180 valves

- from 1.000 to 60,000 b/hour based on200 ML TO 2 litres with water (ambient temp.)./HOT FILL LIQUIDS 95 DEG C

ISOBARIC ACCUFILTRONICS-VM -CP-HF -C

Is an electronic volumetric isobaric filler for bottling carbonated and non-carbonated beverages in PET bottles

This is the most comprehensive configuration, equipped with an extremely flexible “multiproduct” contact valve: the same production line can deal with still, carbonated and hot fill products.

The filling speed can be adjusted according to the product being processed. The configuration of the valve makes it suitable for processing products containing pulp and fibre, also with big dimension pulps.

Output

- Filler from 5 to 180 valves

- from 1,000 to 36,000 b/hour based on 200ML TO 2 litres with CSD (2 to 13°C)./HOT FILL LIQUIDS 95 DEG C

FILLING VALVES-GRAVITY ACCUFILTRONICS VM-GT-WF-NC

It is a weight filler with a very simple, clean and fast filling valve with no contact between valve and bottle. It is a 3 positions diaphragm valve with double filling speed. This solution guarantee high flow performances combined with an extremely accurate and precise product dosing.

Product dosing by means of a load cell.

Weight filling technology is the most reliable and precise system for filling bottles with high-value products such as edible oil, milk, premium clear juices, home and personal care products.

Output:

- Fillers with from 20 to 96 valves

- from 6000 to 36000 bottles/hour on 1.5 litres with edible oil.

FILLING VALVES-GRAVITY ACCUFILTRONICS VM-GT-HF-C

Is an electronic, volumetric gravity filler for PET bottles, equipped with a shuttered filling valve with contact between the valve and the bottle, and double speed filling: this is an extremely versatile valve for hot and cold filling of both smooth and pulpy beverages (also with big dimension pulps).

This solution guarantees an optimization of the filling cycle and of the "brimful" filling.

Output:

- Filler from 50 to 180 valves

- from 10.000 to 42,000 b/hour based on 1,5 litres with fruit juice (85 °C.).

HYGIENE

The sanitation phase is very simple and is fully automatic and controlled by the filler supervision: the machine prepares itself for the electro-pneumatic control of all the on-off valves. The sanitation cycle is carried out in such a way that all the product path is completely cleaned both in equicurrent and countercurrent.

Automatic dummy bottles.

Thanks to the configuration of the filling valve, the filler features an automatic engagement/disengagement system with extremely simple and functional electro-pneumatic control, which ensures there is no contact between operator and machine.

Circuit preset for CIP and SIP up to 100°.

SF FILL

Fillers in the ISOBARIC ACCUFILTRONICS-VM -CP-HF -C range, for carbonated products, are designed to be configured in SF fill version: this means that the carbonating or mixing unit tank will be used as a buffer tank for the filler, which no longer has the product tank on board.

A pump sends the product to a ring-shaped manifold in order to ensure that the product is fed into the filling valve correctly.

Main advantages of this innovative solution are:

- Reduction in product loss < 100 litre (for flavor change)

- The integration of the mixing and filling units produces a final product that is of higher quality and more stable, resulting in an improved filling process.

- Reduction of product change-over downtime: target < 15 min with water rinsing

- Lower electrical power consumption thanks to the light weight design

- Lower consumption of carbon dioxide -10%

- Better performances at the filler start up, able to increase the total Sincro efficiency

HIGHLIGHTS:

Great flexibility: multi product valves allow to handle on the same line still and carbonated, and hot filled products with or without pulps.

High precision of bottled product.

Optimized solutions to handle latest generation of ultra-light bottles.

Automatically engaged dummy bottles

SF FILL configuration available

Reduced changeover down-times.

Valves made entirely of AISI 304, 316 stainless steel.

Filling technology suitable for sensitive products (i.e. CSD without preservatives at 2 to 18°C).

APPLICATION

The main products that can be processed are: carbonated soft drinks (with or without pulps), Carbonated mineral water, non-carbonated mineral water, clear and pulpy juices (also with big dimension pulps), isotonic and sport drink, Sensitive products (fresh or micro-filtered ESL milk, drinking yoghurt etc.), beer, alcoholic beverages, edible oil, home and personal care products.

At the same time, we developed new EVF filling valves, created to be perfectly integrated and interchangeable as part of this new platform.

The range can be equipped with various different feeding solutions:

At the same time, we developed new EVF filling valves, created to be perfectly integrated and interchangeable as part of this new platform.

The range can be equipped with various different feeding solutions:

30-600BPM RFC

30-600BPM RFC